Unless you can see the machinery going on behind the scenes, it’s difficult to tell what kind of elevator you’re riding. Some are better for smaller buildings while others are designed for high rise transportation. Hence there are different types of elevators for a reason. Two most commonly used systems in commercial buildings today are traction elevators and hydraulic elevators.

TRACTION ELEVATORS

The main distinction between traction and hydraulic elevators is how the cab is transported. The cab is hoisted and lowered by traction steel ropes or belts on a pulley system in traction elevators.

Traction Elevators in comparison with hydraulic elevators

- Uses less energy

- Serve Mid to High Rise Buildings

- Ride smoother

A counterweight is used in traction elevators to balance the weight of the cab and its occupants. The motor does not have to transfer as much weight with this arrangement, making it far more energy efficient than hydraulic systems.

The most popular type of elevator is a Traction Elevator. They can be geared or gearless, and they can be powered by either alternating current (AC) or direct current (DC) electrical motors.

Advantages of Self-Supported MRL Elevators (Most Common Traction Elevator)

- Net Travel above 60 ft.

- Fewer requirements for control rooms

- Smaller size Motor

- Smooth and quieter ride

HYDRAULIC ELEVATORS

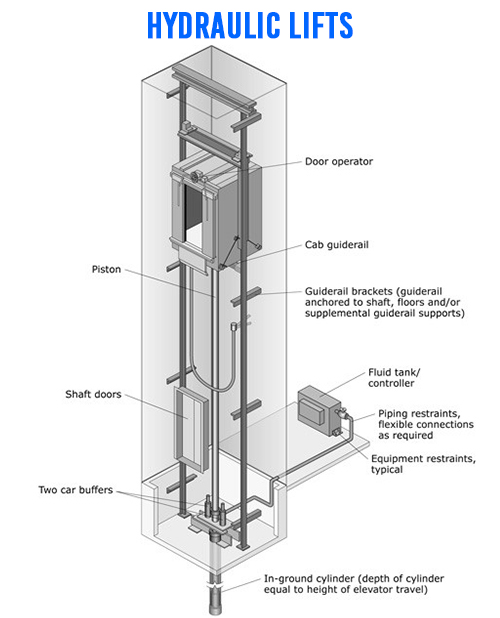

Hydraulic elevators do not require overhead hoisting machinery like traction elevators. Instead, a fluid-driven piston positioned within a cylinder lifts a cab in these elevators. Oil-based fluids have been used in the past, however vegetable oil can be used instead to reduce environmental effect.

Compared to Traction Elevators, Hydraulic Elevators are:

- More affordable to install

- Less expensive to maintain and repair

- Better for transporting heavy loads

- Intended for low-rise applications

Because hydraulic elevators travel at a slower speed than other types of elevators – generally 150ft/min or less – they are most commonly seen in buildings with up to 5 storeys.

Another reason for their height restrictions is because raising an elevator cab many storeys requires a lot of energy. A longer cylinder and piston would be required to reach high floors using a hydraulic elevator.

Advantages of Hydraulic Elevators

- Easiest to Set up

- Install and maintain at the lowest cost

- Capable of transporting heavier loads (i.e. custom cabs)

- Lower pit and overhead requirements with standard travel

- No need of Crane/Roof access

- Above-ground types available with our without machine room

Team Expedite is delighted to assist you with updating your existing system or deciding which type of elevator to put in your new building. Get in touch with us to know more www.expediteautomation.com